Protective Packaging: The Ultimate Solution for Product Safety

Introduction

In a fast-paced, highly competitive marketplace, the importance of protective packaging cannot be overstated. It is not just a barrier between your product and the outside world—it is a vital component that safeguards the product’s integrity, enhances brand reputation, and even plays a significant role in sustainability efforts. Today, more businesses are seeking innovative packaging solutions that offer excellent protection while also being environmentally responsible. Among these solutions, foam protective packaging has emerged as a leader due to its versatility, cushioning properties, and eco-friendly options.

Understanding Foam Protective Packaging: What Makes It Essential?

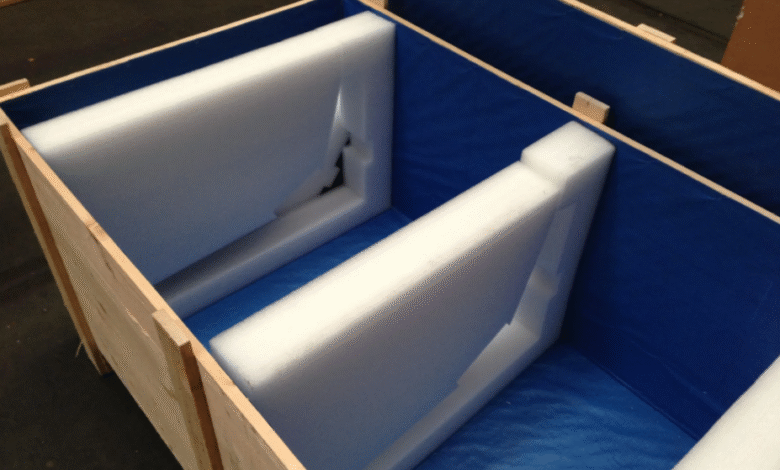

Foam packaging materials such as polyurethane, polyethylene, and polystyrene have been widely used for decades to shield products from damage during storage and transit. The foam’s unique structure absorbs shocks and vibrations, protecting fragile or sensitive goods from impacts. Foam protective packaging can be custom designed to fit specific product dimensions, ensuring a snug, secure fit that traditional packaging simply can’t match.

Beyond protection, foam packaging is lightweight, which can reduce shipping costs and lower carbon emissions during transportation—a critical consideration in today’s drive for sustainability. Moreover, advances in manufacturing have introduced biodegradable and recyclable foam materials, helping businesses reduce their environmental footprint without compromising on quality.

The Complete Protective Packaging Solution: Custom Design and Materials

A one-size-fits-all approach rarely works in packaging. That’s why expert companies specialize in custom design protective packaging tailored precisely to your product’s shape, weight, and fragility. This approach minimizes material waste and maximizes protection, ensuring your product arrives in perfect condition.

Advanced Protective Packaging, a Manchester-based family-run business with nearly 40 years of experience, exemplifies this philosophy. They offer comprehensive packaging solutions that include both the outer cartons and the internal foam fitments. By providing a complete package, they reduce sourcing complexity, cut down on lead times, and streamline inventory management.

Their extensive material options include:

- Polyurethane foam: Known for its flexibility and cushioning.

- Polyethylene foam: Lightweight and resistant to moisture.

- Expanded polystyrene (EPS): Rigid and excellent for impact absorption.

- Nomafoam and Zotefoam: Specialty foams offering high durability and customizability.

With these materials, packaging can be precisely engineered for sectors as varied as medical devices, automotive parts, and electronics, ensuring every product receives the right level of protection.

Eco-Friendly Packaging: Merging Protection with Sustainability

The packaging industry is undergoing a green revolution. With consumers increasingly aware of environmental issues, businesses are pressed to adopt sustainable packaging methods. Protective packaging now goes beyond simply safeguarding products—it must also demonstrate environmental responsibility.

Many companies, including Advanced Protective Packaging, emphasize the reduce, re-use, recycle philosophy. They utilize eco-friendly materials such as recycled polyethylene sheets and biodegradable alternatives, helping clients reduce plastic waste and environmental impact.

Custom-designed packaging made from sustainable materials also elevates brand perception. It signals to customers that the business is socially responsible and environmentally conscious, which can significantly influence purchasing decisions.

See also: 5 Easy Tips to Grow Your Business Network

Benefits of Foam Protective Packaging

1. Superior Product Protection

The primary function of foam protective packaging is to absorb shocks, prevent scratches, and guard against moisture or temperature fluctuations. This protection reduces returns and damage claims, ultimately saving costs.

2. Customization and Brand Differentiation

Custom foam inserts and packaging solutions not only protect but also create a memorable unboxing experience. Tailored packaging enhances brand image and shows customers that you value quality and care.

3. Cost Efficiency

While custom packaging may seem an upfront investment, it reduces product damage and returns, lowering overall expenses. Lightweight foam materials can also cut down shipping fees and simplify warehouse storage.

4. Sustainability and Compliance

Eco-friendly foam packaging options enable businesses to meet regulatory standards and customer expectations for sustainability. Utilizing recyclable or biodegradable materials supports corporate social responsibility goals.

How Advanced Protective Packaging Supports Your Business

Founded in 1986 by Brian Garsden, Advanced Protective Packaging has grown into a leading UK specialist, driven by family values and technical expertise. The company is helmed by Mark Hollingsworth, who, alongside a loyal and knowledgeable team, continues to innovate in the protective packaging field.

They provide expert consultations, bespoke sample creations, and timely delivery to ensure customers receive the best possible packaging solution. Whether you need simple stock products like bubble wrap or complex polyurethane foam inserts, Advanced Protective Packaging offers an array of products tailored for specific industries and applications.

Their extensive product range includes:

- Bubble Wrap (large and small bubble sizes)

- Jiffy Green Padded Bags

- Corrugated Packing Boxes

- Foam Packaging Sheets

- Bubble Lined Envelopes

- Expanded Polystyrene Packing Cubes

- Tape Gun Dispensers

This breadth of products supports businesses in sectors ranging from medical to entertainment, helping them meet protective, branding, and sustainability goals.

Industry Applications of Protective Packaging

Medical Industry

Medical devices require hygienic, shock-absorbent packaging that complies with strict regulations. Foam packaging protects sensitive instruments while maintaining sterility and reducing contamination risk.

Automotive Sector

Fragile automotive parts and components benefit from foam protective packaging’s cushioning properties during transport. Custom foam inserts prevent rattling and damage in high-vibration environments.

Electronics and Entertainment

Delicate electronics and entertainment equipment need packaging that guards against electrostatic discharge and mechanical damage. Foam’s flexibility and protective qualities make it ideal for these applications.

The Future of Protective Packaging: Innovation and Sustainability

The packaging landscape is evolving rapidly with technological advancements and rising environmental consciousness. Innovations like biodegradable foam materials and 3D-printed custom inserts promise to revolutionize protective packaging.

Businesses that prioritize both protection and sustainability will stand out, gaining consumer trust and enhancing brand loyalty. Working with experienced packaging specialists ensures you stay ahead with solutions that balance product safety, aesthetics, and ecological responsibility.

Conclusion

In conclusion, protective packaging, particularly foam protective packaging, is a vital investment for businesses aiming to safeguard their products, elevate their brand, and contribute positively to the environment. From custom design expertise to eco-friendly material choices, companies like Advanced Protective Packaging offer comprehensive solutions that meet the demands of today’s competitive and sustainability-focused market.

By choosing innovative, tailored, and responsible packaging, businesses not only protect their products but also build stronger relationships with customers who value quality and environmental stewardship. Protective packaging is no longer just a necessity—it’s a strategic advantage that drives success and sustainability hand-in-hand.